A1 Variable Frequency Drive

Characteristic

1. Excellent control performance

◆ Support induction motor(IM) and synchronous motor(PM) control

◆ Speed control of SVC (Sensorless vector control) and FVC (Feedback vector control with encoder) : Speed regulation range of SVC is 1:100 and FVC is 1:1000

◆ Support torque control of SVC mode and FVC mode

◆ Speed fluctuation in speed control mode:± 3rpm; torque accuracy in torque mode:± 5%

2. Flexible software functions

◆ Provide free programming module and parameter interconnection, which can be combined and matched freely according to the on-site process

◆ Integrated characteristic functions, such as PID controller, adaptive speed with load, anti sway control, Smooth rotation, etc

◆ Support multiple communication protocols:Modbus, CANopen, PROFINET

◆ Status display via LCD on the Operator Panel in Chinese and English,Support commissioning software based PC——Boneng DriveSoft

3. Strong environmental adaptability

◆ Slim booksize structure to meet side-by-side installation requirements in electrical cabinets

◆Built-in A-class filter(optional), and external filter, meeting the strict electromagnetic level requirements

4. Easy to use and maintainion

◆ Screw free crimping type of IO terminals can be connected and maintained without screw drive

◆ Detachable power terminal, power cable easy to installed conveniently

◆ 105 ° long-life electrolytic capacitor, extending trouble free service life

◆ Advanced semiconductor module and MCU, extremely low failure rate quality assurance

◆ Support induction motor(IM) and synchronous motor(PM) control

◆ Speed control of SVC (Sensorless vector control) and FVC (Feedback vector control with encoder) : Speed regulation range of SVC is 1:100 and FVC is 1:1000

◆ Support torque control of SVC mode and FVC mode

◆ Speed fluctuation in speed control mode:± 3rpm; torque accuracy in torque mode:± 5%

2. Flexible software functions

◆ Provide free programming module and parameter interconnection, which can be combined and matched freely according to the on-site process

◆ Integrated characteristic functions, such as PID controller, adaptive speed with load, anti sway control, Smooth rotation, etc

◆ Support multiple communication protocols:Modbus, CANopen, PROFINET

◆ Status display via LCD on the Operator Panel in Chinese and English,Support commissioning software based PC——Boneng DriveSoft

3. Strong environmental adaptability

◆ Slim booksize structure to meet side-by-side installation requirements in electrical cabinets

◆Built-in A-class filter(optional), and external filter, meeting the strict electromagnetic level requirements

4. Easy to use and maintainion

◆ Screw free crimping type of IO terminals can be connected and maintained without screw drive

◆ Detachable power terminal, power cable easy to installed conveniently

◆ 105 ° long-life electrolytic capacitor, extending trouble free service life

◆ Advanced semiconductor module and MCU, extremely low failure rate quality assurance

Classic application

Cranes, stackers, hoists, extruders, grinders, mixers, crushers, wire drawing machines, plate rolling machines, centrifuges, material transportation, handling, fan pumps , etc.Technical Specifications

Complete structure

The drive is composed of some different functional modules:

◆ Power Module(PM)

◆ Control Module(CM)

◆ Operation Panel(OP) (Optional)

◆ Other optional accessories

The PM and the CM are the two necessary modules that composed drive

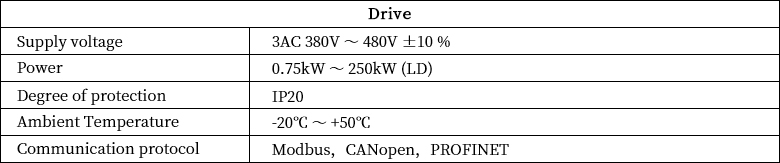

Power Module

PM25 Power Module

◆ The PM25 power module includes a built-in brake chopper(132kW and below) and its efficiency is 95%~97%. Can be installed by wall-mounted, it suits for the general electrical equipment

◆ Ordering data

NOTE: The pm25 modules of built-in filter has no spot stock, please consults the manufacturer if need.

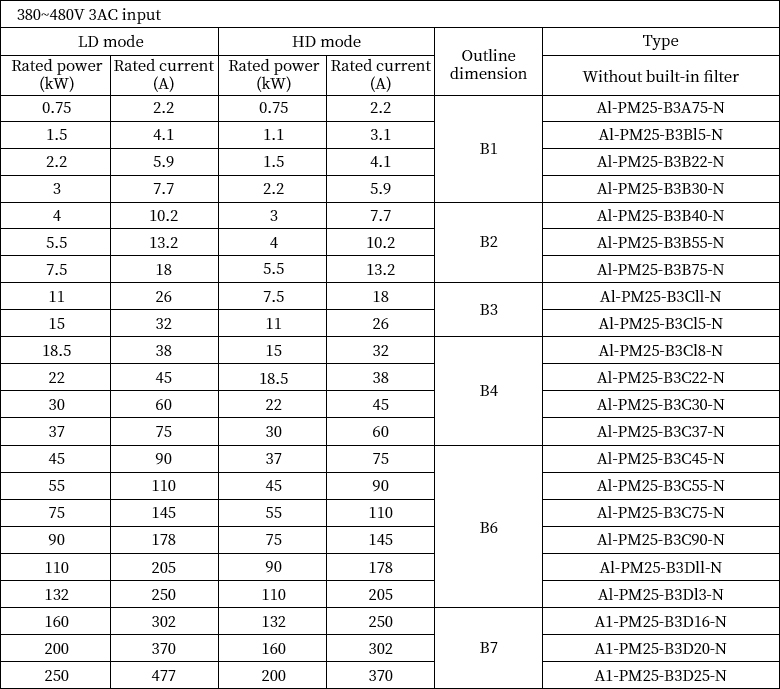

Control Module

CM25 Control Module

◆ CM25 control module provides speed and torque control with or without speed sensor, multiple V/F control of different line types, provides rich interfaces ,such as 10ch-DI , 2ch-DQ, 2ch-AI, 2ch-AQ, and support modbus, CANopen.

◆ Ordering Data

CM22 Control Module

◆ CM22 control module supports closed-loop control functions, it designed for general applications, provides VF or vector control mode(SVC and FVC), support modbus communication and Incremental photoelectric encoder.

◆ Ordering data: A1-CM22-MB-PE

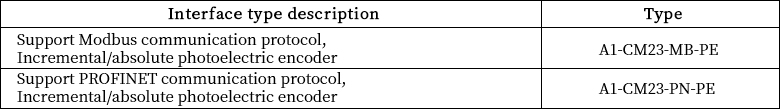

CM23 Control Module

◆ CM23 control module is mainly aimed at the lifting industry. As a special machine for hoist, the digital input is compatible with DC24V, AC36V and AC48V. It can not only provide V / F control, but also support vector control (FVC and SVC), support modbus, PROFINET communication, incremental photoelectric encoder and lifting related characteristic functions.

◆ Ordering data:

Operation Panel

OP25 Operation Panel

◆ TThe OP25 operation panel uses 128*64-point array LCD to display, that can debug and monitor the drive, as well as configuring kinds of parameters. (also supporting extensive line connection, After the cabinet door installation component is selected)

◆ Ordering data: A1-OP25.