AM Variable Frequency Drives

Features

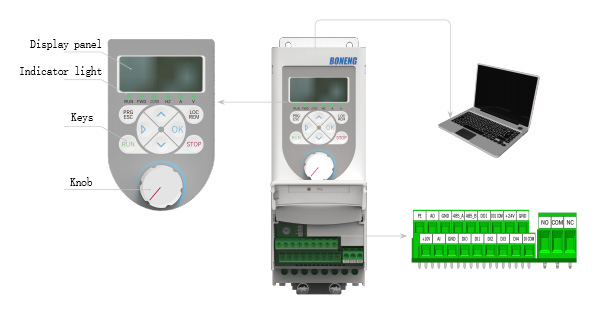

1 User-friendly

| Operation panel | Achieving parameter setting and debugging quickly. |

| Parameters Coping | Debugging one drive and coping parameters to another drive through PC software. |

| Parameters grouping | Reasonably function grouping, simple and intuitive parameters, which are easily to be understood. |

| Supporting Boneng Drivesoft | It's easy to debug through various functions, such as parameters display and modify, virtual oscilloscope, parameters modification list. |

| Built-in Potentiometer | Without external potentiometer, achieving stepless speed regulation through rotating the internal potentiometer. |

2 Realiable quality

| Excellent heat dissipation design | Prolonged service life |

| High quality electronic components/capacitors | low service life cost |

| Tested at full load before all frequency converters are delivered | High reliability |

| Perfect drive protection function | Lean operation |

| Protective coating of PCB is standard configuration. | Prolonged service life |

3 Excellent performance

| Process Proportional Integral (PID) controller | Save external controller. |

| Following presure and speed | Allow running with low voltage to reduce fault downtime. |

| Automaticly identifing motor models | Unleash the full potential of the motor |

| Following load and speed | Limit speed in heavy load condition and raise speed in light load condition to improve efficiency. |

| Tracking start (tracking freely rotating motor) | Avoid starting impact |

| Parameter interconnection | P-Group Interconnect function helps to choose parameter's source flexibly ,such as start and stop command's source , speed reference's source. |

| Freely functional blocks | Functions included logic and arithmetic operation, delay, data selection, suitable for special working conditions parameter setting. |

| Reasonable brake function | Reasonable timing sequence of holding brake logic can achieve the smooth opening and closing of the brake, without slipping the hook. |

4 Compact construction

◆ AM drive power density is optimized. Compact in size and structure, the 3.0kW model has a width of only 70mm, while the 5.5kW model has a width of only 90mm.◆ Support seamless side-by-side installation in the minimum space,which can greatly reduce the size of the control cabinet.

Ordering information

| 380~480V 3AC input | |||||

| LD model | HD model | Overall dimensions | model | ||

| Rated power(kW) | Rated current(A) | Rated power(kW) | Rated current(A) | Without bulit-in filter | |

| 0.75 | 2.2 | 0.55 | 1.7 | M1 | AM-B3A75-N-MB |

| 1.5 | 4.1 | 1.1 | 3.1 | AM-B3B15-N-MB | |

| 3.0 | 7.7 | 2.2 | 5.9 | AM-B3B30-N-MB | |

| 5.5 | 13.2 | 4.0 | 10.2 | M2 | AM-B3B55-N-MB |

Technical parameters

| AM Variable Frequency Drives | ||

|---|---|---|

| Functiobal description | Specification | |

| Basic function | Control Mode | V/F ,SVC |

| Carrying capacity | Heave load (HD):1.5 times rated current output for 1min, 2 times reference current output for 3sec, cycle 10min. | |

| Light load (LD):1.2 times rated current output for 1min, 1.5 times reference current output for 3sec, cycle 10min. | ||

| Torque increasing | Automatic torque increase,Manual torque | |

| V/F control curve | support completely separating various V/F control curve, such as straight line,multipoint,1.5-order, 2-order control curve. | |

| Acceleration and deceleration curves | Two sets of S curves, free switching,acceleration and decelerationtime range 0.0-1000.0s | |

| Multistage speed | 8 constant speed, can be switched by terminal or interconnection parameters | |

| Inching operation | Moving at a frequency:0.0%~100.0%,Slope at:0.0-1000.0s | |

| DC braking | Braking time:0.00s~100.00s,Braking current: 0.0%~100.0% | |

| RPM track and start again | Realize the smooth starting of the rotating motor without impact | |

| Stall control in overcurrent and overvoltage | Automatic limit of current and voltage during operation to avoid frequent trip | |

| Process Proportional Integral(PID)controller | Conveniently realizing the closed-loop control system of process quantity (such as pressure, temperature, flow rate, etc.) | |

| Industrial bus | Communication bus | Modbus RTU |

| IO | DI | 5 channels, optical coupler isolation, support 36V AC input |

| AI | Channel 1,0~10V | |

| Relay output | Channel 1, programmable, Max switching voltage 250VAC/30 | |

| DO(transistor) | Channel 1, programmable | |

| AO | Channel 1,0~20mA | |

| Others | Protection grade | IP20 |

| Temperature | -10℃~+50 ℃ | |

| EMC | IEC 61800-3 C2 | |