S-MX Helical-Worm Servo Gearmotor &AX Servo Drives (0.22kW~6.6kW)

Features

◆ High modular design, biomimetic surface with owned intellectual property right.◆ Adopt integral casting box, small volume, strong bearing capacity, smooth transmission, low noise.

◆ Perfect anti-oil leakage performance, more reliable sealing, more applicable to a wide range of working conditions.

◆ Gear adopt advanced grinding technology and modification technology, high bearing capacity, reliable operation.

◆ Save cost and low maintenance.

◆ Servo motor not only has a strong compact structure and high protection grade, but also has high efficiency, high overload bearing capacity and other characteristics;Its excellent radial runout quality and subtle torque fluctuation can realize high quality workpiece surface machining.

◆ Combined with boneng Agile series drive to form a powerful servo system, can achieve seamless integration, perfect coordination.

Design of geared motor

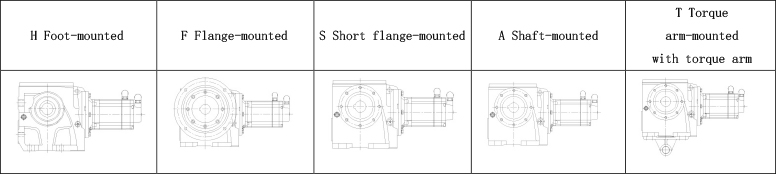

◆ Transmission stage:2 stage.◆ Mounting Mode:

◆ Output shaft: Solid shaft, hollow shaft (parallel key, shrink disk, involute spline)

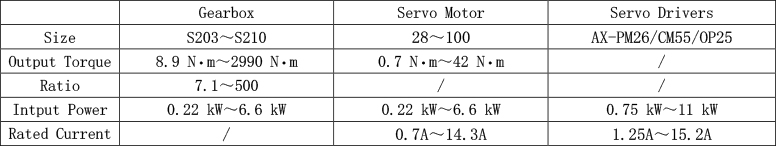

Technical data

AX Servo Drives

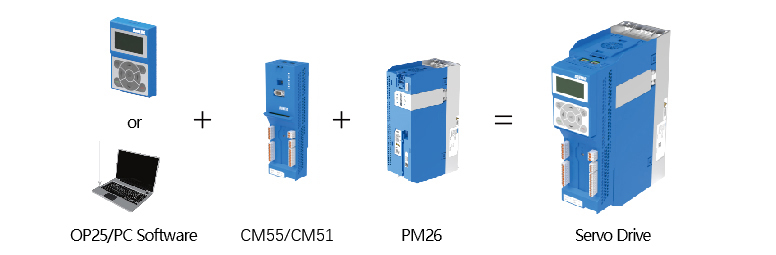

AX precision series servo drives are modular servo drives designed for high-performance servo applications with a unified control module, and composed of a power module adapted to different power servo motors and some optional accessories, the flexible modularization provides users with richer options for system design and application. AX precision series single-axis servo drive consists of three parts:

Operation panel (OP25) or PC debugging software BonnegDrivesoft:

operation panel or PC debugging software can provide users with convenient and quick parameter setting methods, supports Chinese character display, more simple and understandable information feedback, and advanced oscilloscope detection and diagnosis functions.

Control module (CM55):

The control module provides users with a wealth of control interfaces, input and output terminals, analog signals, and communications, and through a variety of ways to control and monitor the connected motor.

Power module (PM26):

The book-type power module has a power range from 0.75kw-132kw, supports a variety of control modules, makes motor speed adjustment simple and flexible, and includes complete drive protection functions.

Features

◆ Modular design, flexible product combination;◆ PROFINET and EtherCAT communication supported, just choose different control modules;

◆ Wide power range, covering from 0.75kW-132kW;

◆ High-precision 23-bit absolute value encoder used for high control precision;

◆ 380VAC voltage level design, eliminating additional configurations such as transformers;

◆ Fast screw-free control terminals, convenient for wiring, debugging and maintenance;

◆ Abundant IO interfaces and optional Bi-direction control terminals.

Technical data

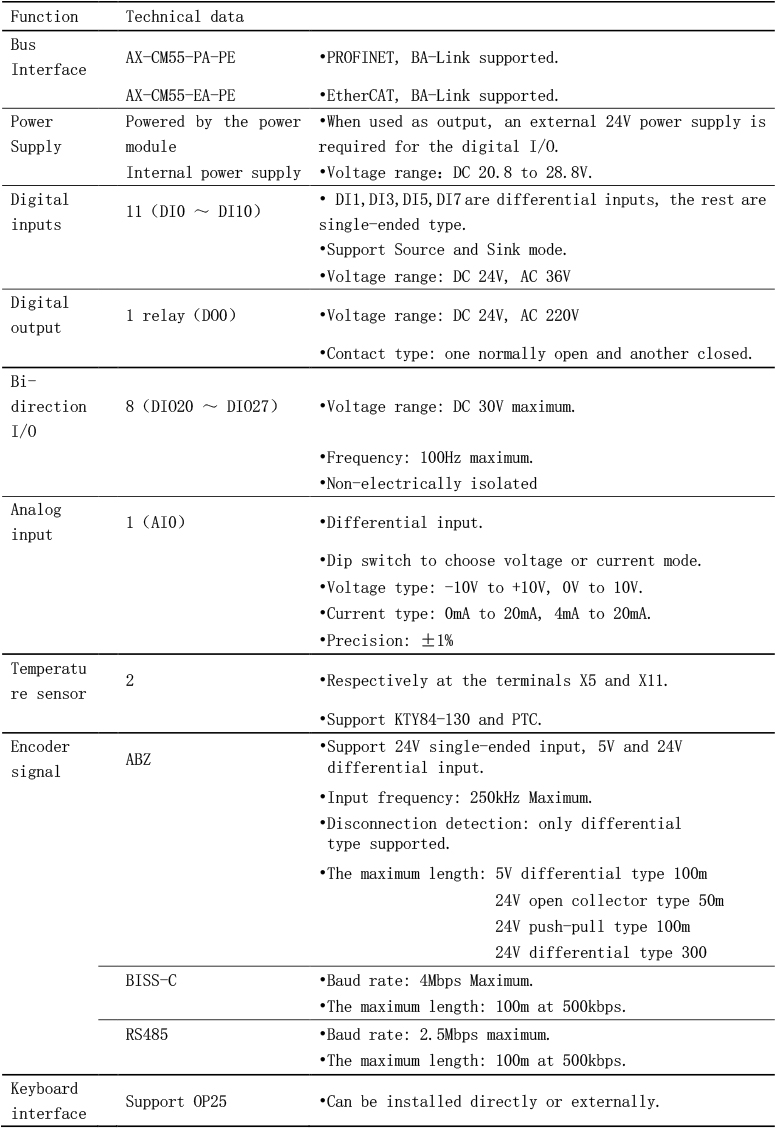

1.Control module

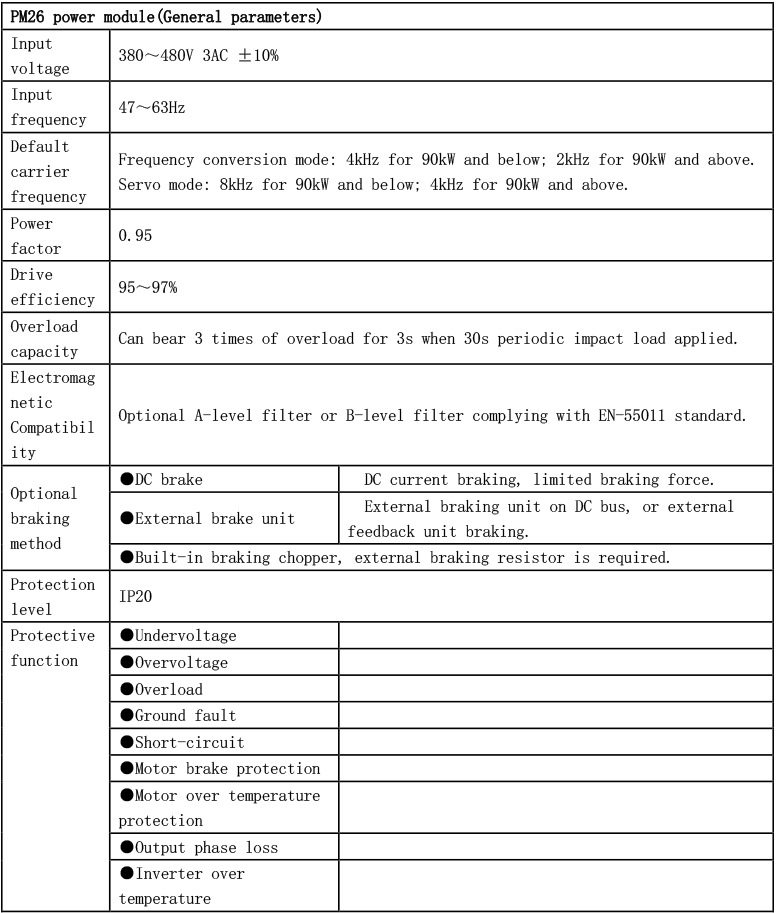

2.Power module

Main application industries

◆ Automation equipment industry◆ Printing machines

◆ Packaging machines

◆ Textile machinery

◆ Manipulator